Innovation in

manufacturing methods

Innovation in

technology and processes

Continuous innovation paves the way for high-quality development.

Only by Embracing Innovation Can We Truly Excel Through Economic Ups and Downs

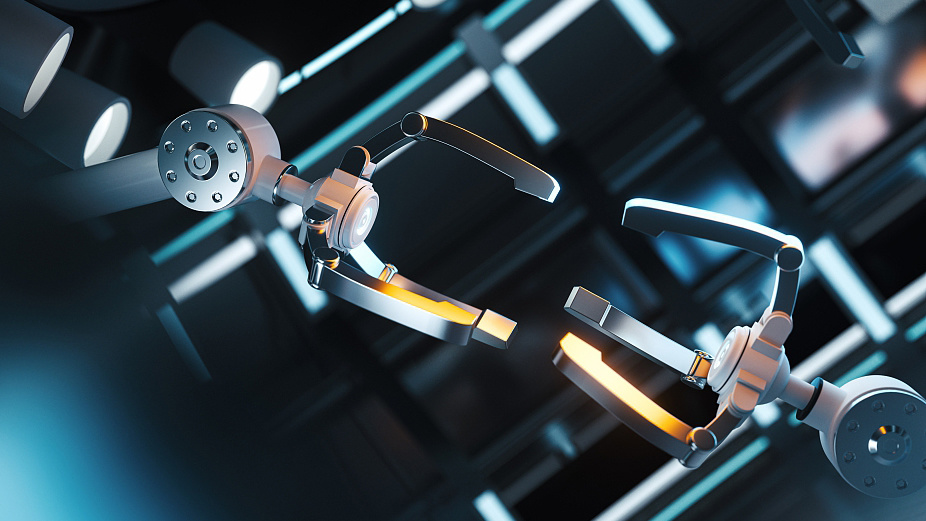

Intelligent Manufacturing

Lean Manufacturing

Intelligent Operations

Precision and Digital Intelligent Manufacturing

Building smart factories equipped with intelligent devices, digital and IT systems, and modern management practices.

Closed-Loop Management for Autonomous Monitoring,

Analysis, Decision-Making, and Optimization

Intelligent Warehousing and Logistics

Real-Time Intelligent Planning and Scheduling

End-to-End Quality Traceability

Intelligent Detection of Wafer Defects

Intelligent Analysis of Inspection Data

Integrated Data Platform

Continuously Promote Technological Innovation

Floating Zone (FZ) Process

Czochralski (CZ) Process

This process is suitable for applications in memory, logic, CIS, DDIC, and power products.

Polishing Process

Epitaxial Process