Services for Silicon-Based Products

Wafer Type Selection

Polished Wafers

Epitaxial Wafers

SOI Wafers

Argon-Annealed Wafers

SiC Epitaxial Wafers

Silicon-based GaN Epitaxial Wafers

Other Products

Product Specifications

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 300mm | MCZ/CZ |

<100> <110> <111> |

N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 200mm | MCZ/CZ |

<100> <111> |

N,P |

| FZ |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| ≤150mm | CZ/FZ |

<100> <111> |

N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 300mm | MCZ/CZ |

<110> <100> |

N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 200mm | MCZ/CZ |

<100> <111> |

N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| ≤150mm | CZ |

<100> <111> |

N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 300mm | SOI |

<100> |

N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 200mm | SOI |

<100> |

N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 300mm | MCZ |

<100> |

P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 200mm | MCZ/CZ |

<100> |

P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 200mm | / | <11-20> | N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| ≤150mm | / | <11-20> | N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| 200mm | EPI | <0002> | N,P |

| Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|

| ≤150mm | EPI | <0002> | N,P |

| Lapped Wafers | Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|---|

| ≤150mm | CZ/FZ |

<100> <111> |

N,P |

| Etched Wafers | Product Size | Process | Orientation | Conductivity Type |

|---|---|---|---|---|

| ≤150mm | CZ/FZ |

<100> <111> |

N,P |

Features and Applications

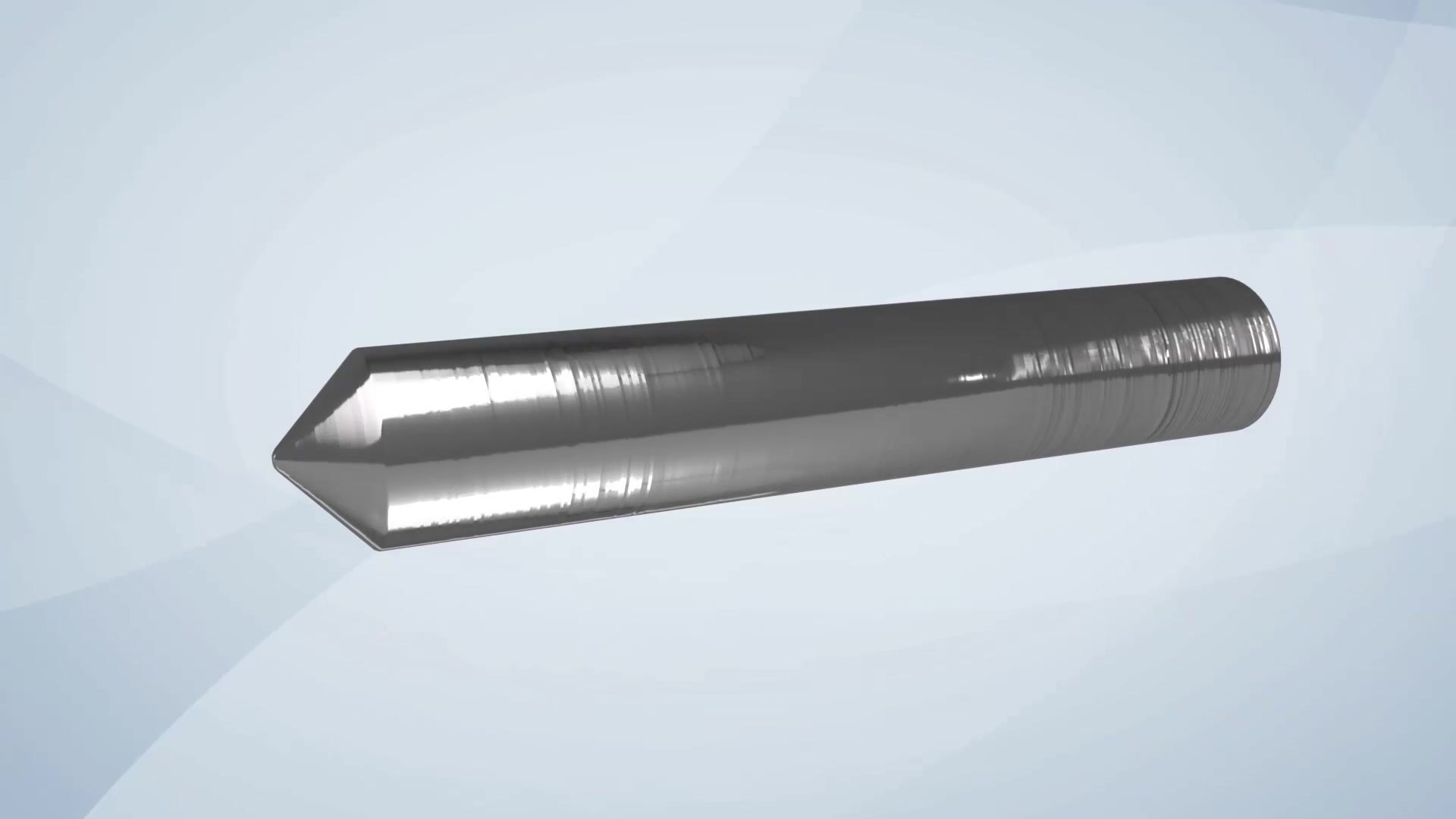

FZ

Features

High voltage

High current

Application

High-voltage electric power

Microelectronic devices

Frequency converters, voltage regulators, etc

CZ

Heavy

Doping

Features

Energy

efficient

Application

Power switches

High frequency

Optical sensors

Image sensors, etc

MCZ

Light

Doping

Features

High storage density

High-performance computing

Low power consumption

Application

Memory chips

Analog chips

Logic chips, etc

GaN

SiC

3rd-Gen Semiconductor Materials

Features

High temperature resistance

Radiation resistance

High frequency

High conversion efficiency

Application

Efficient fast charging

Traction inverters for new energy vehicles